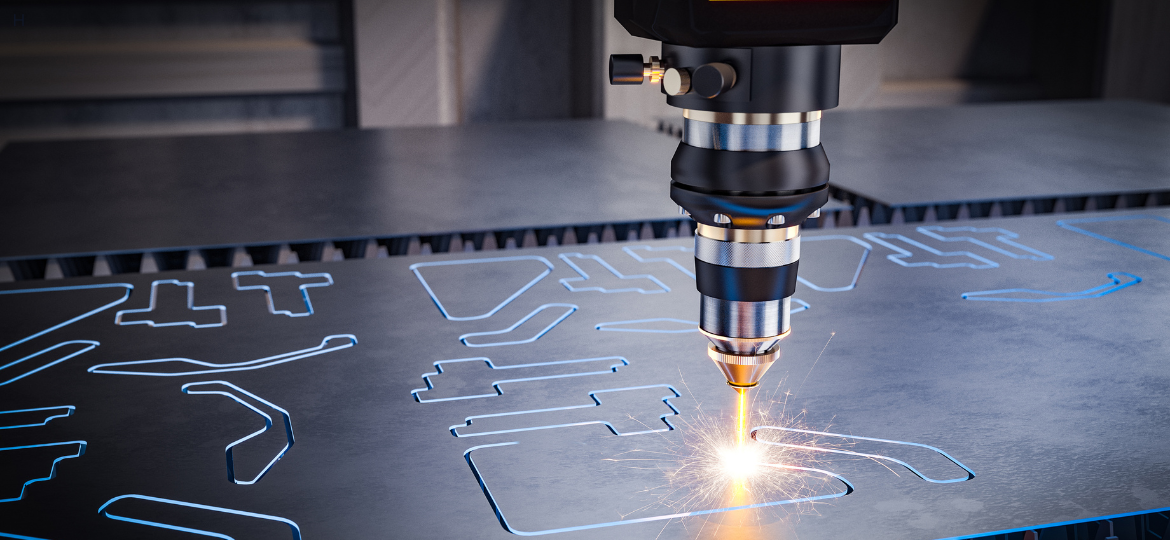

A Digital Twin Model for Design and Development of Cutting Tools with Macro and Micro

Revolutionizing Cutting Tool Design!

Swinburne University of Technology is thrilled to partner with Sutton Tools Pty Ltd on this exciting venture. Together, they’ll be developing digital twin model of cutting tools to improve their performance.

Project Overview:

Imagine a highly accurate digital counterpart of a cutting tool, allowing for precise performance evaluation and design optimisation. That’s exactly what this project aims to achieve! By leveraging advanced 3D modeling, The Research team will automate measurements, compare performance across designs and comprehend the impact of both macro and micro geometries on tool performance.

Collaboration is Key:

This project embodies a powerful partnership between Swinburne University’s expertise in Advanced Machining Technologies and Sutton Tool’s industry leadership in manufacturing of cutting tools. This project embodies a collaborative approach that bridges the gap between academia and industry, fostering a win-win situation.

Industry Impact:

As Mr. Keith Petrzela (Group Technical Manager & Industry Supervisor) at Sutton Tools states, “it is imperative that Sutton Tools remain at the forefront of cutting tools geometry specifically targeting the aerospace industry.”

Academic Significance:

Prof. Suresh Palanisamy (Director of Manufacturing Futures Research Platform & Academic Supervisor) and Dr. Rizwan Abdul Rahman Rashid (Postdoctoral Research Fellow & Academic Supervisor) state that “Swinburne and Sutton Tools have a long-standing relationship that spans over number of decades. This collaboration will further strengthen, leading the way in developing cutting-edge digital technologies to enhance productivity and innovation within the cutting tools manufacturing sector while also fostering sovereign capability.”

Student Spotlight:

PhD Candidate Angelo Papageorgiou (R&D Engineer), brings his skills and experience to the table and is “very excited to be starting my National Industry PhD Program, working together with Swinburne in developing new methodologies for cutting tool design.”

Project Outcomes & Impact:

This project aligns perfectly with Sutton Tools’ core R&D goals. By developing a cost-effective digital model, they can overcome the limitations of expensive physical prototypes. Ultimately, the project fosters collaboration between academia and industry, enriches research capabilities, and cultivates a talent pipeline with expertise in advanced manufacturing and digital technologies. Additionally, it strengthens Swinburne University’s role in driving innovation and economic growth within Australia’s manufacturing sector.